HTS Vacuum Furnaces are employed across a wide range of industrial sectors thanks to their advanced capabilities in vacuum and high-vacuum heat treatment.

From the aerospace and energy industries to automotive, tooling and mould manufacturing, and extending to micro-mechanics, watchmaking, and the medical sector, HTS provides solutions tailored to diverse requirements, ensuring precision, efficiency, and uniformity in all treatments.

In the aerospace sector, HTS furnaces process critical components such as engines, turbines, gears, and shafts, which are subject to high mechanical stresses, enhancing their mechanical properties and performance under extreme conditions. The equipment complies with international standards such as NADCAP and AMS2750, providing certified reliability.

In the energy sector, the HTS team, leveraging extensive field experience, designs and manufactures furnaces that deliver versatility, flexibility, and maximum process reliability.

Within the automotive industry, particularly in the high-performance sector where components must withstand intense loads, vacuum furnace treatments ensure optimal performance: uniform hardness, absence of oxidation or distortion, and full preservation of surface characteristics.

In tooling and mould production, HTS furnaces improve mechanical properties and extend tool life, ensuring uniform heating and controlled cooling, which are essential for complex processes such as hardening, tempering, and carburising.

The micro-mechanics and watchmaking sectors demand extreme precision: HTS furnaces provide the thermal control required to process delicate components, optimising their mechanical properties without compromising integrity. Similarly, in the medical sector, HTS delivers solutions compliant with the highest standards, guaranteeing reliability and consistent results.

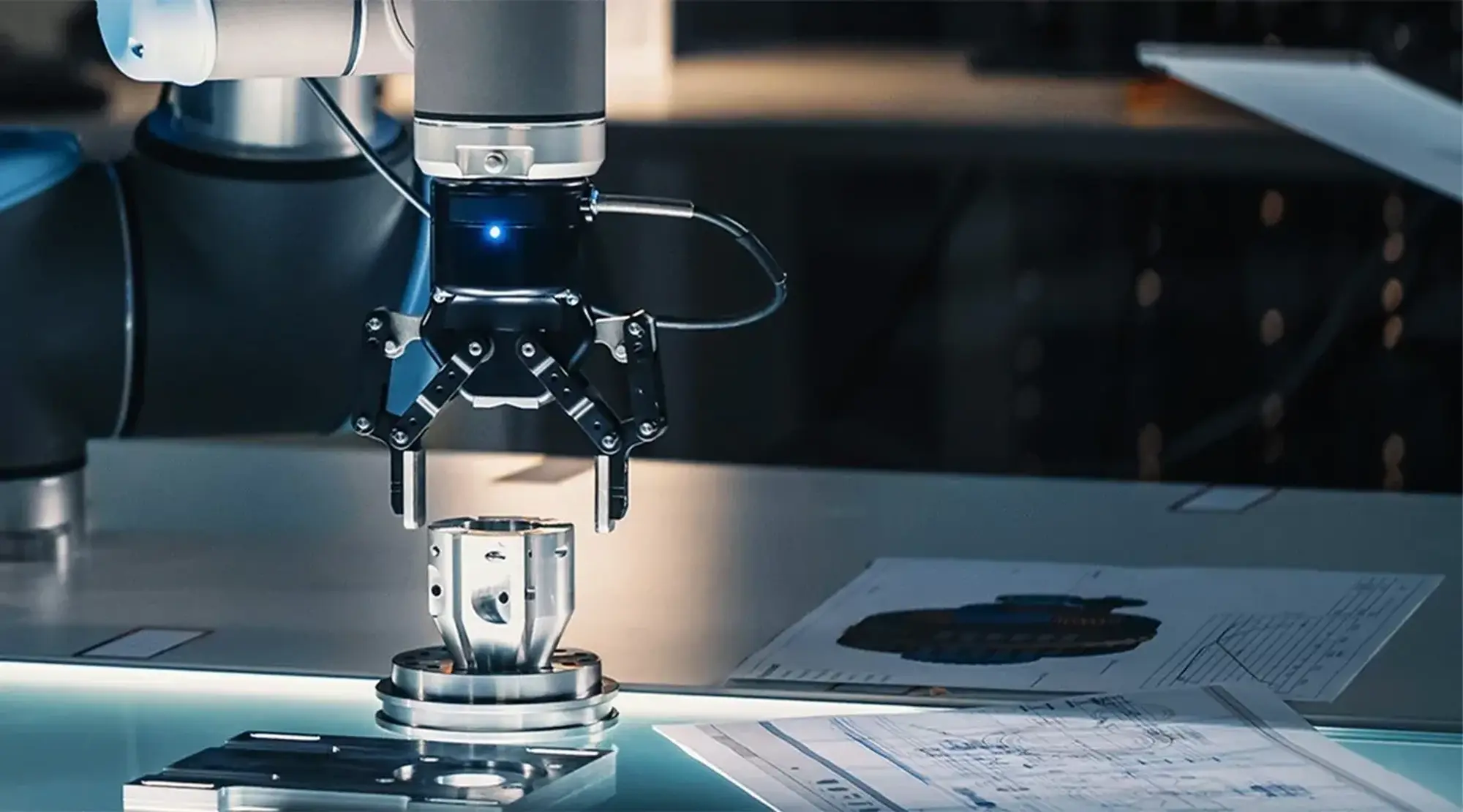

HTS also serves the additive manufacturing sector, where metallic components produced by 3D printing require specific post-print heat treatments to achieve the desired mechanical properties and performance.

Beyond these applications, HTS stands out for core values that guide every project: precision, innovation, flexibility, dedicated technical support, high-quality materials and processes, and solid industrial experience. HTS’s approach ensures that each furnace, treatment, and service is customised to the client’s needs, minimising oxidation and contamination while delivering uniform and reproducible results.

Choosing HTS means partnering with a company that combines advanced technology with strong values, capable of supporting businesses and research centres in the most strategic sectors with reliable, precise, and bespoke solutions.