In the context of the medical device industry, the adoption of innovative technological solutions is essential to ensure compliance with stringent regulations and product safety. In this scenario, HTS industrial furnaces emerge as essential elements, offering a wide range of tailor-made solutions designed to meet specific needs.

Vacuum heat treatments for the dental sector

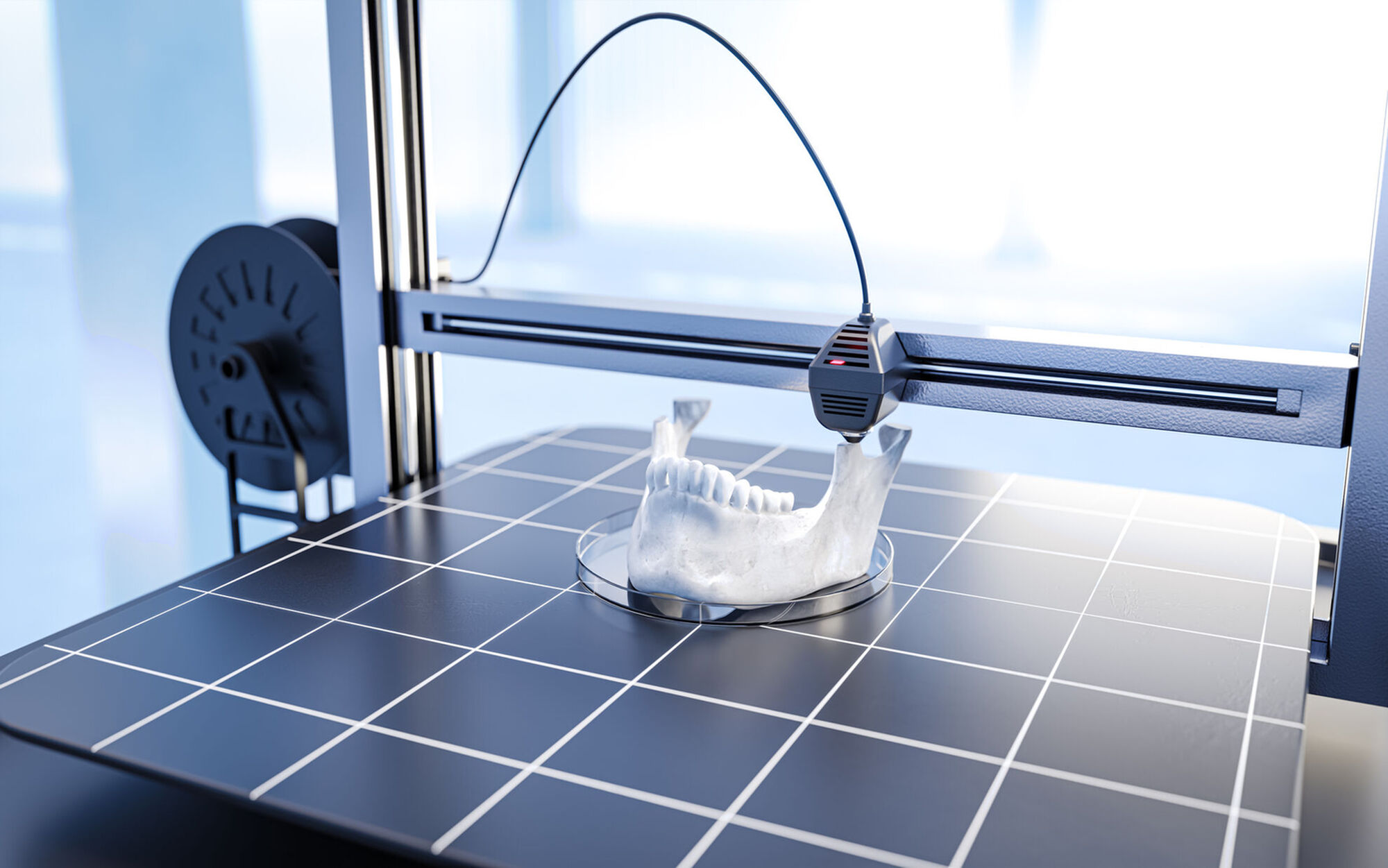

Vacuum heat treatment plays a fundamental role in the production of advanced dental devices. During the printing process, the use of laser on metal powder can lead to undercooling phenomena, causing unwanted mechanical tensions. However, through the application of stress relief heat treatments in a vacuum environment, it is possible to eliminate these tensions, ensuring the stability and quality of the produced components. The Research and Development department of HTS Furnaces conducted thorough tests on printed samples, demonstrating that the integration of controlled temperatures and a high level of vacuum has produced significant results in improving the characteristics of titanium dental prostheses. In particular, low-temperature heat treatments have been identified as essential for reducing residual stresses accumulated during the 3D printing process, while higher temperatures have contributed to optimizing the mechanical properties and microstructure of the material. It is crucial to emphasize that, despite the changes in material properties, the geometric dimensions of the components must remain constant to ensure perfect compatibility with the implant and the patient's mouth.

HTS Vacuum Furnaces: guarantee of safety and compliance

In the field of medical devices, compliance with regulations and safety are paramount. HTS furnaces play a crucial role in maintaining stringent standards during production processes, ensuring controlled and stable temperatures to prevent contamination or alterations of the devices. Thanks to their versatility and ability to work with a variety of materials, these furnaces offer customized solutions to meet the specific needs of the medical device sector, ensuring maximum safety and quality of the final products.

Tailored solutions for industrial excellence

The adaptability of HTS furnaces to the specific needs of the pharmaceutical and medical device industries is a key element for business success. Thanks to the ability to precisely control parameters such as temperature, vacuum, and atmosphere, these furnaces allow accurate and reproducible heat treatment of the materials used. Furthermore, the ability to monitor and record process parameters ensures traceability and regulatory compliance, essential elements to maintain the quality standards required by regulatory authorities.